Calcium carbonate is rich in resources, simple in processing technology, and has many excellent characteristics, so calcium carbonate is very versatile.

Application of calcium carbonate

Calcium carbonate industry use

Calcium carbonate is an important building material with a wide range of industrial applications. Widely used in papermaking, metallurgy, glass, alkali making, rubber, pharmaceutical, pigments, organic chemicals and other sectors.

It is commonly used in the construction industry and paper industry, also can be used as an additive in the food industry. When used as a calcium supplement, the absorption rate is 39%, second only to calcium fruit acid, and it is soluble in gastric acid. It has become the calcium supplement with the most dosage forms and most applications.

- It can be used for various feed additives within 200 mesh, with calcium content of 55.6% or more and no harmful ingredients;

- 250-300 mesh can be used as raw material for plastic factory, rubber factory, paint factory, waterproof material factory and interior and exterior wall painting, whiteness above 85 degrees;

- 350-400 mesh can be used to make gussets, drain pipes, and chemicals, with whiteness above 93 degrees;

- 400-600 mesh can be used for toothpaste and soap, whiteness above 94 degrees;

- 800 mesh can be used for rubber, plastic, cable, PVC, whiteness above 94 degrees;

- 1250 mesh can be used for PVC, PE, paint, coating grade products, papermaking primer, papermaking topcoat, whiteness above 95 degrees;

- 2500 mesh can be used in calendering film, edge banding, corrugated pipe, artificial leather, shoe material, engineering plastics, amino film plastic, wire and cable, powder coating, oily coating and other industries to improve the hardness and whiteness of materials and reduce costs;

- 2800 meshe is widely used in engineering plastics, wire and cable, powder coatings, oil-based coatings, calendered films, edge banding, corrugated pipes, artificial leather, shoe materials and other industries;

- 3000 mesh is widely used in electrical glue, powder coating, calendered film, printing ink and other industries.

Uses of heavy calcium carbonate

Calcium carbonate for rubber

400 mesh, 93% whiteness requirement, 96% calcium carbonate content. Calcium carbonate is one of the most used fillers in the rubber industry. A large amount of calcium carbonate filled in rubber can increase the volume of its products, obtain higher tensile strength, tear strength and wear resistance than pure rubber vulcanizates, while saving expensive natural rubber and reducing production costs.

Calcium carbonate for plastics

400 mesh, 95% whiteness requirement, 99% calcium carbonate content. It is required that the whiteness remains unchanged after high temperature heating, and the ore structure is large crystalline calcite. Calcium carbonate plays a skeleton role in plastic products, has a great effect on the dimensional stability of plastic products, and can improve the hardness of products and the surface gloss and surface smoothness of products.

Calcium carbonate for paint

800 mesh or 1000 mesh, 95% whiteness requirement, 96% calcium carbonate content. The amount of calcium carbonate in the paint industry is relatively large, and the amount in thick paint is more than 30%.

Calcium carbonate for water-based paint

800 mesh or 1000 mesh, 95% whiteness requirement, 96% calcium carbonate content. Calcium carbonate has a wide range of uses in the water-based coating industry. It can endow coatings with characteristics such as non-sedimentation, easy dispersion, and good gloss. The amount of water-based coatings is 20-60%.

Calcium carbonate for papermaking

325 mesh, 95% whiteness requirement, 98% calcium carbonate content. Calcium carbonate plays an important role in the paper industry, which can ensure the strength and whiteness of the paper, and the cost is low.

Calcium carbonate for construction

325 mesh, 95% whiteness requirement, 98% calcium carbonate content. Calcium carbonate plays an important role in concrete in the construction industry, not only can reduce production costs, but also increase the toughness and strength of the product.

Calcium carbonate for fireproof ceiling

600 mesh, 95% whiteness requirement, 98.5% calcium carbonate content. Calcium carbonate is mainly used in the production process of fireproof ceilings, which can improve the whiteness, brightness and fireproof performance of the product.

Calcium carbonate for floor tiles

400 mesh, 95% whiteness requirement, 98.5% calcium carbonate content. Pure calcium carbonate without impurities is used in the floor tile industry to increase the whiteness and tensile strength of the product, improve the toughness of the product, and reduce the production cost.

Calcium carbonate for ink

In the ink industry, stearic acid-modified calcium carbonate is used. The formulated ink has good viscosity, good printing performance, and high stability. The fine particles are easily compatible with other raw materials, so the printed product is smooth , The dots are complete, the covering power is strong, and the gloss is high. As a filler, heavy calcium can improve the gloss and brightness of the ink.

Calcium carbonate for breathable film

Calcium carbonate material can be added to the breathable membrane as a breathable material. It is one of the important components in the production and processing of the breathable membrane material. The breathable membrane is also called “waterproof and breathable microporous membrane”, which is characterized by breathability and impermeability. The breathable membrane is made of PE The carrier is formed by adding a certain proportion of calcium carbonate and being stretched, so that the breathable film has a unique, high-density distribution, and numerous interconnected micropores with special structures.

Calcium carbonate for adhesives

Calcium carbonate can be used in wood processing adhesives, construction adhesives, sealants, heat shrinkable adhesives, pressure sensitive adhesives, glass adhesives and other industries. Calcium carbonate has a good affinity with rubber compounds, which can accelerate the cross-linking reaction of the glue, greatly improve the thixotropy of the system, enhance the dimensional stability, and improve the mechanical properties of the glue. It is added in a large amount to achieve double filling and reinforcement effect. At the same time, it can make the rubber surface bright and delicate.

Calcium carbonate for other industries

Calcium carbonate can also be used as an additive to emerging additives, such as flame retardants, stabilizers and other industries, can add heavy calcium carbonate. In addition, food and pharmaceutical grade heavy calcium carbonate can be used in medicine, cosmetics, food additives, feed and other industries.

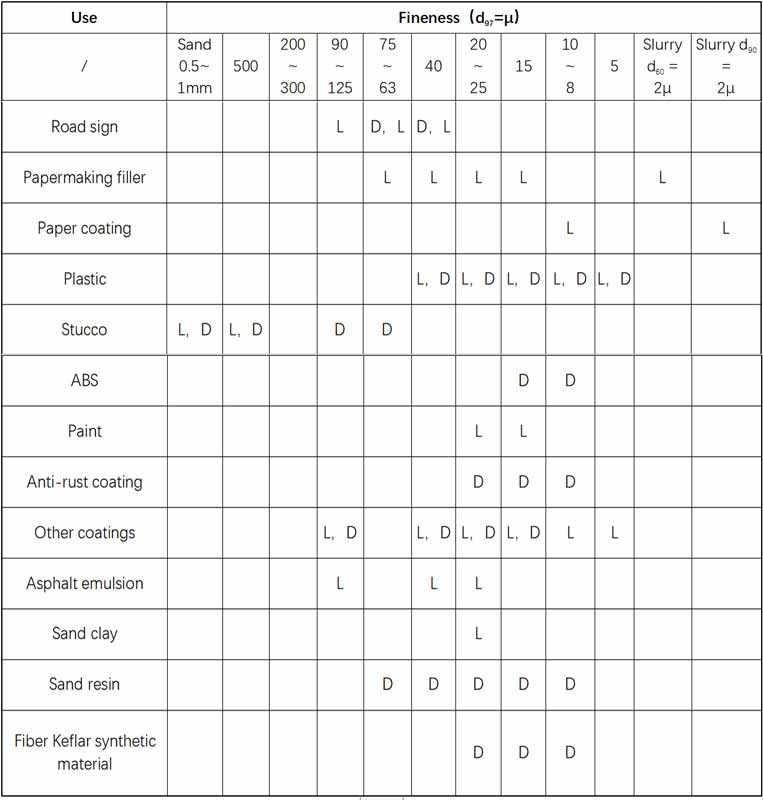

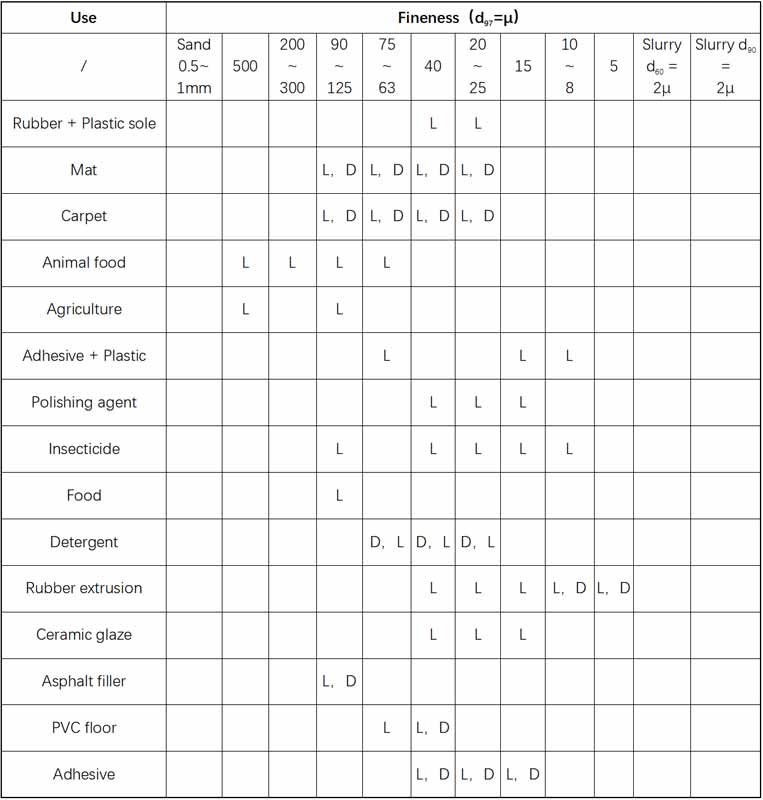

List of uses of ground calcium carbonate and dolomite

Note: L-calcium carbonate, D-dolomite. Compared with PCC, the processing process of GCC has the advantages of being more economical and environmentally friendly. In industrial applications, there is a trend of replacing light calcium with heavy calcium.

Uses of precipitated calcium carbonate

It can be used as a filler in industries such as rubber, plastics, papermaking, coatings and inks. It can also be used as a raw material for tooth powder, toothpaste and other cosmetics. It is widely used in the production of organic synthesis, metallurgy, glass and asbestos. It can also be used as a middle seeding agent for industrial wastewater, an antacid for gastric and duodenal ulcers, an antidote for acidosis, a SO₂ detoxifier in exhaust gas containing SO₂, an additive for dairy cattle and an anti-sticking agent for linoleum.

Uses of colloidal calcium carbonate

It can be used as a filler for rubber to give rubber a bright color, high elongation, high tensile strength, and good wear resistance. When producing microcellular rubber, it can be foamed uniformly. It can also be used as a filler in industries such as artificial leather, wire, polyvinyl chloride, coatings, inks and paper making, so that the finished product has a certain tensile strength and a smooth appearance.