Surface modification is an important means to improve the application performance of calcium carbonate, improve its applicability, and expand the market and dosage. Then, after surface modification, what will happen to the “life” of calcium carbonate?

More popular, “versatile”

Unmodified calcium carbonate can only be used as a traditional filling material, and its application field and dosage will be limited to a certain extent. Through surface modification, calcium carbonate has turned into a multifunctional modifier, with better functional application effect, to meet the requirements of different fields, and the application range is wider, and different modification methods and modifiers are used to achieve its functional purpose. For example, activated calcium carbonate modified by fatty acid (salt) can be used in the fields of polyolefin plastics, cable materials, adhesives, inks, coatings and the like. After the surface of light calcium carbonate is coated with silica, it can partially replace silica and supplement the deficiencies of silica in some properties. After the surface of light calcium carbonate is coated with metal, some special properties of rubber products can be improved.

More dispersed, no longer “groups of three or five”

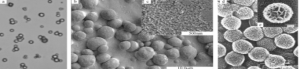

Ultrafine pulverization is an important way to improve the quality of calcium carbonate, but with the ultrafineness and nanometerization of calcium carbonate, the smaller the particle size and the more atoms on the surface, the higher the surface energy and the stronger the adsorption effect. , according to the energy principle, each particle must be agglomerated with each other, and cannot be well dispersed in the polymer matrix. There are many nano calcium carbonate products on the domestic market. Under the scanning electron microscope, it does reach the nano level, but in practical applications, its effect is not better than that of fine calcium carbonate. The reason is that nano calcium carbonate has not undergone surface modification. The agglomeration between particles is serious, the diameter of secondary particles is far from nano-scale, and the uniformity of particle size is poor, which can only be regarded as “nano calcium carbonate” in name. Through surface modification, the modifier can be directionally adsorbed on the surface of calcium carbonate, so that the surface has charge characteristics. Due to the repulsion of the same charge, calcium carbonate is not easy to agglomerate, which has a good dispersion effect and better dispersion.

More gregarious, able to “get in” with resin

Calcium carbonate without surface treatment has poor compatibility with resin, which is easy to cause uneven dispersion in the polymer base material, resulting in interface defects of the composite material and reducing the mechanical strength of the material. These disadvantages become more pronounced as the dosage increases. Through surface modification, the interfacial compatibility and affinity of calcium carbonate can be increased, thereby improving its physical properties with composite materials such as rubber or plastic. For example, calcium carbonate treated with titanate coupling agent has good compatibility with polymer molecules. At the same time, since the titanate coupling agent can form molecular bridges between calcium carbonate molecules and polymer molecules, it enhances the interaction between polymers or resins and calcium carbonate, which can significantly improve the performance of thermoplastic composite materials. Mechanical properties such as impact strength, tensile strength, flexural strength, and elongation. The surface-modified calcium carbonate has better interface affinity.

More valuable and “impressive”

At present, the production capacity of ordinary calcium carbonate in my country is overcapacity, and the competition of low-price products is fierce. The surface-modified calcium carbonate has a significantly improved use effect, a good user experience, and a natural increase in value. Of course, the price of calcium carbonate modified with different meshes is also different. In addition, the composite modification of particles with titanium dioxide coated calcium carbonate can replace titanium dioxide to a certain extent, and its value-added is greater. The surface-modified calcium carbonate has high added value and doubles its value!

Looking forward to the future, functionalization will become the main trend in the development of calcium carbonate, and the product structure will also undergo great changes. Products such as nano-scale calcium carbonate, ultra-fine calcium carbonate and food-grade calcium carbonate; various surface-modified calcium carbonates, such as natural rubber, synthetic rubber, light calcium carbonate for coatings, the market demand for these high value-added calcium carbonate products will increase. It is getting bigger and bigger, and the quality of products will also be the key to the survival and development of enterprises!