Single Rotor/Multiple Rotor

Single Rotor/Multiple Rotor

With horizontal staged turbine, the rotor speed can be adjusted by frequency conversion, and the particle size distribution can be adjusted flexibly, classifying efficiency (extraction ratio) can be 60%~90%, available D50:1.5-25μm.

Features:

High speed, accurate vertex cutting; clean production process; program control system, easy to adjust and operate.

Application:

Widely used in chemical industry, mineral industry (especially suitable for classification of non mineral products such as calcium carbonate, kaolin, quartz, talc, mica), metallurgy, abrasives, ceramics, refractory, medicine, pesticide, food, health care products, new materials, etc..

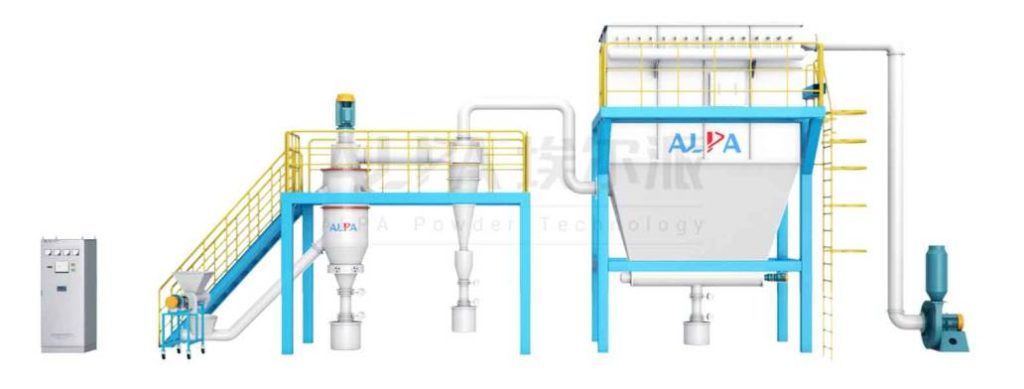

The classifier and cyclone separator, dust collector and induced draft fan form a classifying system. Under the action of fan suction, the material is moved from the lower inlet of the classifier to the classifying zone with the ascending airflow. Under the strong centrifugal force generated by the high-speed rotating turbine, the materials are separated and the fine particles which meet size requirements through the classifier impeller gap into the cyclone separator or the dust collector, the coarse particles entrained part of the fine particles collided with the wall and the velocity disappeared, descending along the cylinder wall to the secondary air outlet, and the coarse and fine particles were separated by the strong washing action of the secondary air. The fine particles rise to the classification zone for secondary classifying, and the coarse particles are lowered to the discharge port for discharging.

Single Classifying Wheel

| Parameters/specifications | FW200 | FW280 | FW400 | FW520 | FW630 | FW800 |

|---|---|---|---|---|---|---|

| Production Capacity(kg/h) | 10~100 | 20~200 | 50~500 | 100~1500 | 200~2500 | 400~4000 |

| Production Particle size (D97:μm) | 3~45 | 3~45 | 3~45 | 3~45 | 3~45 | 5~45 |

| Classifying efficiency(%) | 60~80 | 60~80 | 60~80 | 60~80 | 60~80 | 60~80 |

| Installed Power(kW) | 7~11 | 15~19 | 21~28 | 23~30 | 52~60 | 67~77 |

Multiple Classifying Wheel

| Parameters/specifications | FW400/3 | FW400/4 | FW630/3 | FW630/4 | FW630/6 | FW800/4 | FW800/6 | FW1000/4 | FW1000/6 |

|---|---|---|---|---|---|---|---|---|---|

| Production Capacity(t/h) | 0.2~1.5 | 0.3~2 | 1~5 | 2~8 | 3~10 | 3~10 | 5~15 | 5~20 | 8~30 |

| Production Particle size (D97:μm) | 3~45 | 3~45 | 3~45 | 3~45 | 3~45 | 5~45 | 5~45 | 5~45 | 5~45 |

| Classifying efficiency(%) | 60~80 | 60~80 | 60~80 | 60~80 | 60~80 | 60~80 | 60~80 | 60~80 | 60~80 |

| Installed Power(kW) | 60~90 | 175~100 | 135~155 | 170~190 | 250~290 | 220~290 | 290~390 | 340~440 | 500~580 |