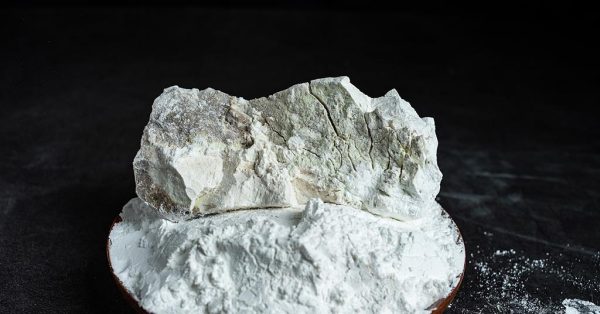

The Ca2+ and CO32- unsaturated particles produced during the mechanical crushing of heavy calcium carbonate easily react with adsorbed water molecules to produce hydroxyl groups, making heavy calcium carbonate hydrophilic. However, organic polymers are lipophilic and hydrophobic. The opposite surface properties of the two lead to poor compatibility, uneven dispersion and weak interfacial bonding of heavy calcium carbonate in the organic polymer matrix, which makes it easy for polymer-based composite materials to produce interface defects during use and reduce their performance. Therefore, the surface of heavy calcium carbonate must be organically modified.

At present, commonly used surface modifiers can be mainly divided into coupling agents, surfactants, composite modifiers, superdispersants and inorganic substances.

Coupling agent surface modifiers

The modification mechanism of aluminate coupling agent to modify heavy calcium carbonate is that the alkoxy group at one end of the aluminate structure reacts chemically with the hydrophilic hydroxyl group on the surface of CaCO3.

The modification mechanism of titanate coupling agent to modify calcium carbonate is that the titanate coupling agent forms a Ti-O chemical bond with CaCO3, forming a new molecular film on the surface of CaCO3, which is hydrophobic and enhances the fluidity of CaCO3.

Silane coupling agents are widely used, but conventional silane coupling agents have a small number of hydroxyl groups and are difficult to react chemically with heavy CaCO3. The price of silane coupling agents that can successfully modify heavy CaCO3 is high, and it is difficult to produce them on a large scale in industry.

Surfactant modifiers

Fatty acid surfactants are anionic surfactants. The structure of one end of the molecular chain is a long-chain alkyl structure similar to the polymer structure, so it can be well compatible with the polymer matrix, while the structure of the other end of the molecular chain is a polar group that can react physically and chemically with the surface of CaCO3.

The modification mechanism of phosphate surfactants is that phosphate reacts chemically with CaCO3 to form a phosphate coating, thereby changing the surface of CaCO3 from hydrophilic to hydrophobic.

Quaternary ammonium salt surfactants are cationic surfactants. One end of the molecular chain can cross-link with the polymer, while the other end can adsorb with the surface of CaCO3 through positive charge.

Compound coupling treatment modifiers

Compound coupling treatment modifiers are mainly based on coupling agents, and are combined with surfactants or cross-linking agents to modify CaCO3, and their synergistic effect is used to achieve better modification effects to increase the surface activity of CaCO3.

Hyperdispersant modifiers

Hyperdispersants are amphiphilic structures, one end of which is an anchoring group that can adsorb to the surface of solid particles, and the other end is a solvated chain that is easily dispersed in a polar matrix. Different solvated chains are suitable for dispersion in different polar matrices.

Inorganic modifiers

Inorganic modifiers are often used to reduce the pH value of heavy CaCO3, increase its acid resistance, and enhance the dispersibility of CaCO3 in water. They mainly include condensed phosphoric acid, silica, etc.

Surface modification plays a vital role in improving the application value and performance of heavy calcium carbonate. In the processing and production, the research on modifiers should be strengthened, and surface modifiers, auxiliary modifiers and modification equipment should be selected in a targeted manner according to the surface modification mechanism, the properties of the base material, the technology of the processing technology and other requirements.