Nano drug carrier refers to a new type of carrier with a particle size of 10 to 1000 nm. Because its particle size is much smaller than that of capillary access, and it has the advantages of reducing drug toxicity and side effects, improving drug stability, slow-release and controlled-release drugs and drug targets. Due to its advantages such as release, nano-drug carriers are widely used in the field of medicine.

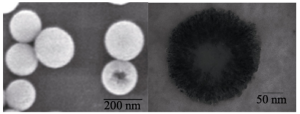

Among nano-drug carriers, nano-microspheres, as a new drug-carrying material, have received more and more attention in recent years. The preparation of calcium carbonate into nano-microspheres is relatively simple, and the calcium carbonate material has the advantages of superior biocompatibility, biodegradability, and acidity responsiveness. Clinically, nano-microspheres prepared from calcium carbonate for drug loading can slow the release of antitumor drugs, reduce adverse reactions, and improve the therapeutic effect, which has greater advantages than other inorganic materials [2].

The drug carriers designed in the past decades of research work usually only have one or two functions of sustained release, environmental responsiveness, targeting, and combined drug loading, but how to integrate these functions into drug carriers? Among them, it is one of the research focuses in the field of pharmacy in recent years. Especially for the design of antitumor drugs, efforts are made to integrate these functional materials on the same drug carrier in some ways to form a multifunctional drug carrier.

The advantages of nano calcium carbonate in the field of drug loading

Security

Because calcium carbonate nanospheres have good biocompatibility and degradability, they will not cause secondary human toxicity after decomposing under acidic conditions, and may also have the effect of calcium supplementation, which will not cause any harm to the human body.

Functionality

Calcium carbonate nanospheres have a porous structure, which has a relatively high specific surface area, can efficiently load tumor drugs, and is very suitable as a drug-loading material.

Feasibility

The cost of calcium carbonate is relatively low, the preparation conditions are mild, and organic solvents are not used, which greatly reduces the toxic and side effects of the human body. The development of calcium carbonate-based drug-carrying systems has great application market potential and is easy to modern industrial production.

Preparation of drug-loaded nano-calcium carbonate

Emulsification Technology

The inverse microemulsion technology is mainly used, that is, the W/O microemulsion droplets are used as nano-reactors, and the aqueous inner phase containing calcium ions is mixed with the organic phase to form a W/O microemulsion, and carbonic acid is added to the system at the same time. The aqueous solution of salt ions was mixed until CaCO3 particles were formed, and the nanoparticles were then centrifuged.

Chemical precipitation

CaCO3 nanoparticles are prepared by reacting calcium ions in aqueous solutions such as calcium chloride or calcium nitrate with carbonate ions in aqueous solutions such as sodium carbonate. Different factors, such as homogenization speed, Ca2+/CO32- ratio, presence of surfactants and inducers, and drug concentration may affect the particle size and drug loading rate of CaCO3 nanoparticles. For example, high homogenization speed will lead to higher mechanical shear force, which can effectively reduce particle size.

Preparation method of hollow microspheres

Solvent evaporation method

Solvent evaporation is a common method for preparing hollow microspheres. Generally, two kinds of solvents are used to mix and dissolve the carrier material, and the commonly used mixture is a mixture of ethanol/dichloromethane, or a mixture of isopropanol, acetone, diethyl ether, etc. In the curing and drying stage of the microspheres, the solvent with higher solubility or better volatility in the continuous phase will diffuse and remove faster, so that the polymer outside the emulsion droplets is precipitated, cured, and deposited to form a film; while the other solvent diffuses and volatilizes slowly, and the internal The polymer then solidifies, shrinking from the inside out, forming a cavity in the center.

Template method

The template method is characterized in that the shell material is adsorbed and solidified onto the template material driven by hydrogen bonding, electrostatic action, etc., and finally the template is removed by solvent dissolution, high temperature calcination, cleaning, etc., to obtain hollow microspheres. Materials that can be used as templates include polymer microspheres, surfactants, micelles, and vesicles.

Preparation method of porous microspheres

Solvent evaporation method

The operation process of preparing porous microspheres by solvent evaporation method is basically the same as the preparation process of hollow microspheres. The difference is that the preparation of porous microspheres requires the addition of porogens. Porous Microspheres.

Suspension polymerization

Suspension polymerization is also a commonly used method for preparing porous microspheres. In the presence of the suspending agent, the polymerizable monomer, the initiator and the porogen are suspended in the liquid phase matrix to carry out the polymerization reaction, and the porogen is removed after the reaction is completed to obtain porous microspheres. Commonly used porogens in the reaction are organic solvents and linear polymers.

Epilogue

The drug carrier material is the most important part of the drug delivery system. Its development and application are not only related to the improvement and improvement of the efficacy of traditional drugs, but also contribute to the research and development of new drugs and solve difficult problems in the history of human disease cure. At present, drug carrier materials have been successfully used in the treatment of various diseases, but there are still some problems to be solved. How to reduce the toxicity of the carrier material and avoid its side effects, how to make the carrier material better participate in human metabolism, so that it can be excreted with human metabolites faster.

In addition, the main development trends of drug carrier materials and related technologies can be summarized into two points. One: use a suitable nano-drug carrier to encapsulate the active ingredient with poor solubility but good curative effect, so that it can maintain its activity and stability before reaching the action site, so as to exert its curative effect. The second is to prepare nano-drug carriers and combine with specific drugs to obtain nano-smart drugs with targeted and quantitative timed drug release, so as to solve the diagnosis and treatment of major diseases such as cancer and cardiovascular disease.