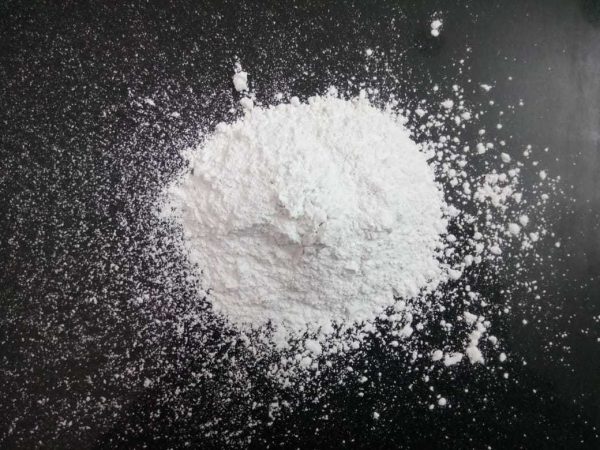

what is calcium carbonate

Calcium carbonate is an inorganic compound with the chemical formula CaCO₃, which is the main component of limestone, marble, etc. Calcium carbonate is basically insoluble in water and soluble in hydrochloric acid (reacts with hydrochloric acid). It is one of the common substances on the earth. It exists in aragonite, calcite, chalk, limestone, marble, travertine and other rocks. It is also the main component of some animal bones or shells. Calcium carbonate is also an important building material and is widely used in industry.

Types of Calcium Carbonate

According to different production methods of calcium carbonate, calcium carbonate can be divided into heavy calcium carbonate, light calcium carbonate, colloidal calcium carbonate and crystalline calcium carbonate.

1. Ground calcium carbonate

Heavy calcium carbonate (commonly known as heavy calcium) is produced by directly crushing natural calcite, limestone, chalk, shells, etc. by mechanical means (using Raymond mill or other high-pressure mills).

2. Light calcium carbonate

Light calcium carbonate (commonly known as light calcium carbonate), also known as precipitated calcium carbonate, is calcined limestone and other raw materials to generate lime (mainly composed of calcium oxide) and carbon dioxide, and then add water to digest the lime to produce lime milk (mainly composed of calcium hydroxide), Then carbon dioxide is added to carbonize lime milk to form calcium carbonate precipitate, and finally it is obtained by dehydration, drying and crushing. Or use sodium carbonate and calcium chloride to carry out metathesis reaction to generate calcium carbonate precipitate, then dehydrate, dry and pulverize.

3. Colloidal calcium carbonate

Colloidal calcium carbonate, also known as activated calcium carbonate, modified calcium carbonate, surface-treated calcium carbonate, colloidal calcium carbonate or Baiyanhua, referred to as live calcium, is the use of surface modifiers to modify the surface of light calcium carbonate or heavy calcium carbonate. made by sex. Since the calcium carbonate modified by the surface modifier generally has a reinforcing effect, that is, the so-called “activity”, it is customary to call the modified calcium carbonate active calcium carbonate.

Properties: white fine, light powder, a layer of fatty acid soap adsorbed on the surface of the particles, so that CaCO3 has colloidal activation properties. The specific gravity is 1.99~2.01.

4. Crystal calcium carbonate

Properties: pure white, hexagonal crystal powder. The specific volume is 1.2-1.4 ml/g. Soluble in acid, almost insoluble in water.

5. Nano calcium carbonate

Nano-calcium carbonate (ultrafine calcium carbonate) has good affinity with resin when used in plastics, which can effectively increase or adjust material rigidity, toughness and bending strength, etc., and can improve the rheological properties of plastic processing systems and reduce plasticizing temperature. Improve product size stability, heat resistance and surface smoothness; in NR, BR, SBR and other rubber systems, it is easy to mix and disperse evenly, and can make the gum soft, and can also improve extrusion processing performance and mold fluidity. The rubber product has the characteristics of smooth surface, high elongation, high tensile strength, small permanent deformation, good bending resistance and high tear resistance.

Industrial uses of calcium carbonate

Calcium carbonate is the trade name of limestone, a valuable resource with a wide range of uses, as a mineral raw material. Limestone has been widely used in the history of human civilization because of its wide distribution in nature and easy access. As an important building material, it has a long mining history. In modern industry, limestone is the main raw material for making cement, lime, and calcium carbide. It is an indispensable flux limestone in the metallurgical industry. High-quality limestone is widely used after ultra-fine grinding. Used in the manufacture of paper, rubber, paint, coatings, medicine, cosmetics, feed, sealing, bonding, polishing and other products. According to incomplete statistics, the ratio of limestone consumed in cement production to construction stone, lime production, metallurgical flux, and limestone consumed in superfine calcium carbonate is 1:3. Limestone is a non-renewable resource. With the continuous progress of science and technology and the development of nanotechnology, the application field of limestone will be further expanded.

1. Application in plastic production

Calcium carbonate is widely used in polyvinyl chloride (PVC), polyethylene (PE), polypropylene (PP), acrylonitrile butadiene-styrene copolymer (ABS) and other resins. Adding calcium carbonate has a certain effect on improving some properties of plastic products and expanding their application range. In plastic processing, they can reduce resin shrinkage, improve rheological state, and control viscosity. It can also play the following roles:

(1) Improve the dimensional stability of plastic products;

(2) Improve the hardness and rigidity of plastic products;

(3) Improve plastic processing performance;

(4) Improve the heat resistance of plastic products;

(5) Improve the astigmatism of plastics;

(6) It can make the product have some special properties;

(7) Reduce the cost of plastic products.

2. Application in food industry

It can be used as an additive in the food industry. For example, it can be used in various feed additives, with a calcium content of over 55.6% and no harmful ingredients. It can be used as a calcium supplement, with an absorption rate of 39%, second only to calcium fruit acid, soluble in gastric acid, and has become the calcium supplement with the most formulations and applications.

3. Application in construction industry

It can be used as a raw material for plastic factories, rubber factories, paint factories, waterproof material factories and for painting interior and exterior walls. It has the characteristics of high purity, high whiteness, non-toxic, odorless, low fine oil quality and low hardness. Marble is also an important building material that can be used in house construction.

4. Application in chemical manufacturing industry

350 mesh to 400 mesh can be used to make gussets, downpipes, and chemicals. The whiteness is above 93 degrees. 400 mesh to 600 mesh can be used for toothpaste paste, soap. The whiteness is above 94 degrees. 800 mesh can be used for rubber, cable, pvc, and the whiteness is above 94 degrees. It can also be used in the manufacture of optical neodymium glass raw materials, etc.