Surface modification with important practical significance to improve the properties of the powders, increase the practical value and develop the application fields.

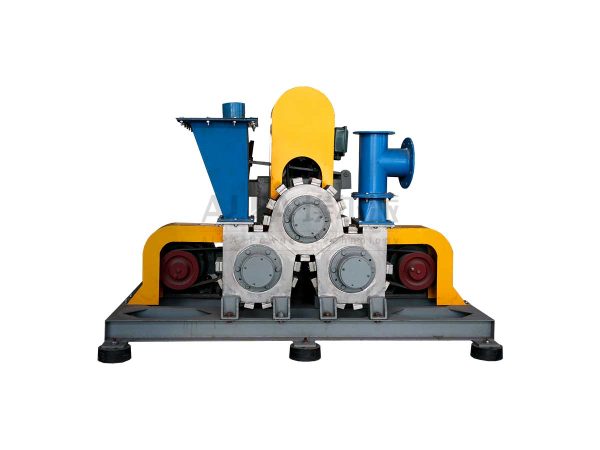

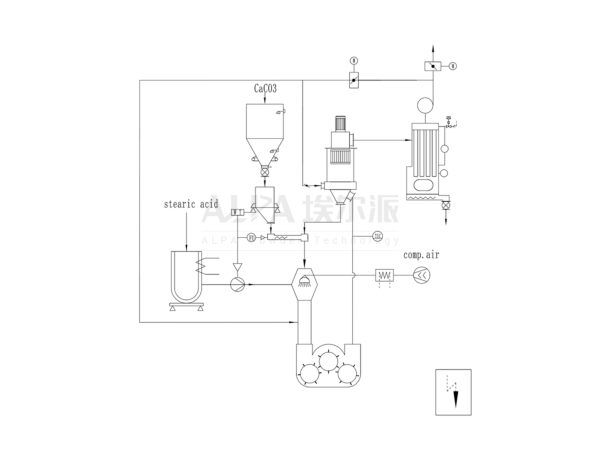

In plastics, rubber, adhesives and other polymer materials and composite materials, nonmetal powder fillers, such as calcium carbonate, kaolin, talc, quartz, wollastonite, asbestos, magnesium hydroxide, aluminum hydroxide, etc., must be modified on surface to enhance its compatibility with matrix, dispersion, mechanical strength and comprehensive properties.

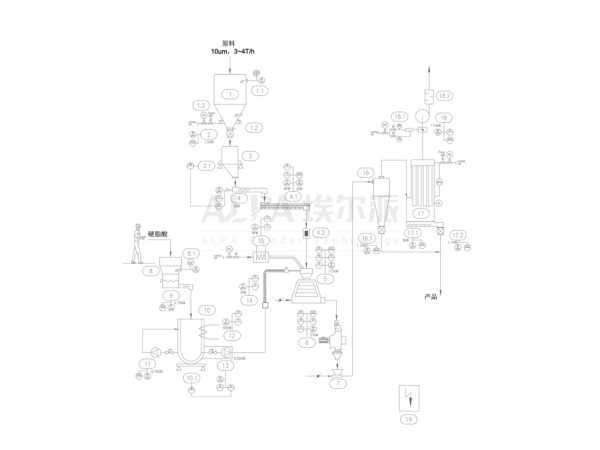

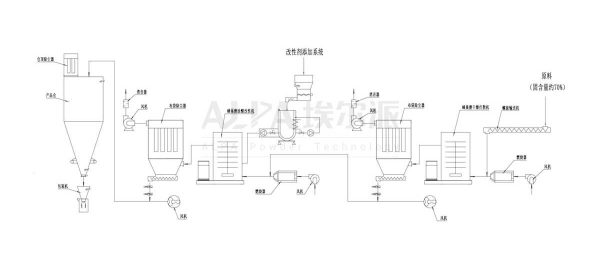

Surface modification is one of the necessary processing methods for filling materials from general incremental fillers to functional fillers, and it is also the main purpose of surface modification of mineral fillers. The main functions of surface modification of mineral fillers include dispersion, viscosity reduction, filling and interfacial mechanics. The most commonly used modification methods are surface chemical modification, coating modification and mechanochemical modification. The research contents include modification mechanism, modifier, modification process and equipment, process control, product testing and evaluation, etc.