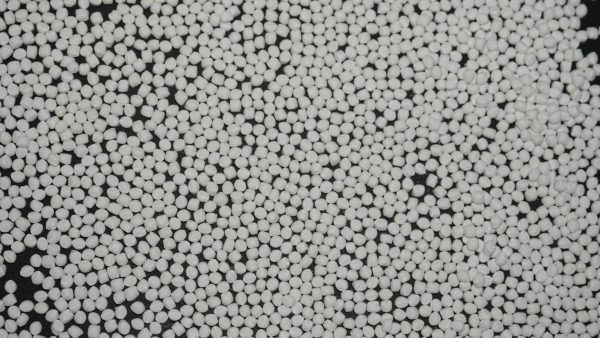

Among filling and modified materials for plastics, calcium carbonate occupies an unshakable and important position. Calcium carbonate can be divided into heavy calcium carbonate and light calcium carbonate. So, in plastic products, is it better to use light calcium carbonate or heavy calcium carbonate? okay?

1. Conceptual difference

First of all, heavy calcium and light calcium should be given an accurate definition of the concept.

Some people use sedimentation volume (using absolute ethanol as the sedimentation medium) to distinguish heavy calcium from light calcium. That is, the sedimentation volume above 2.5 mL/g is light calcium, and the sedimentation volume 1.2-1.9 mL/g is heavy calcium carbonate.

We distinguish them from the different production processes. Heavy calcium is made by mechanically crushing and sorting ore, while light calcium is made by calcining, digesting and re-carbonating the ore.

Some people mistakenly believe that light calcium is lighter due to the fact that the same weight of calcium carbonate has different volumes when naturally accumulated. In fact, the apparent density of the two is different, but the real density difference is very small. The real density of heavy calcium is 2.6-2.9g/cm3, while light calcium is 2.4-2.6g/cm3.

2. Differences in application effects

Someone has done a comparative test of adding heavy calcium and light calcium into rubber. The conclusion is that under the same dosage and the same processing conditions, adding heavy calcium is easier to mix and process, and it is easier to disperse in the rubber matrix, and adding heavy calcium is better than adding light calcium. The tensile strength is high, but the rubber filled with heavy calcium has a large shrinkage rate and a rough surface. The heavy calcium used is -400 mesh, and its price is only half of that of light calcium used in comparison, and its economic benefits are very considerable.

The use of heavy calcium and light calcium in plastic products is similar to rubber products. Some manufacturers reported that using -400 mesh heavy calcium instead of light calcium under the same conditions has obvious advantages for products sold by weight. However, if products are sold by length, area or number, heavy calcium is no better than light calcium. Calcium has an advantage.

3. Use heavy calcium or light calcium? cannot be generalized

From an academic point of view, there are many differences between heavy calcium and light calcium, such as different crystal forms, different specific surface areas, different oil absorption values, etc. Moreover, the particle size and distribution of -400 mesh heavy calcium and light calcium are very different. In what form do the heavy calcium or light calcium particles exist in the plastic matrix? Are they individually distributed in the matrix macromolecules, or are they in clusters and distributed in the matrix resin in the form of loose aggregates? And these particles The state of the interface with the resin macromolecules is directly related to the mechanical properties of the material.

Whether to use heavy calcium or light calcium in plastic products cannot be generalized. The decision should be made based on giving full play to their respective advantages and combining technical and economic factors.

The production of plastic profiles is gradually developing towards large-scale and mass production. The substitution and replacement of a raw material is related to the quality and stability of a large number of products. Therefore, plastic product processing plants will not easily replace a certain component in the formula.

4. How can calcium carbonate be better used in the plastics industry?

Calcium carbonate has become one of the indispensable raw materials in the plastics industry. The rapid development of the calcium carbonate industry has provided the plastics industry with material conditions for selection and exploration. Its good application in plastic materials has also guided the development of the calcium carbonate industry.