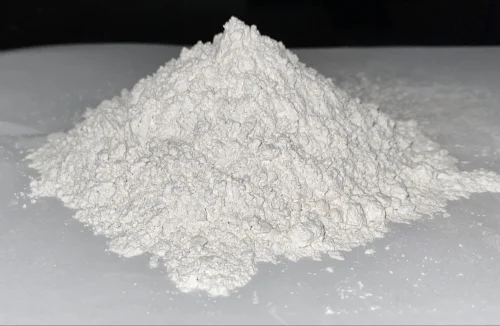

According to different regions, production costs, material costs, and the whiteness of heavy calcium carbonate powder, the price of 400 mesh heavy calcium carbonate powder also varies greatly. Heavy calcium carbonate powder 400 mesh is usually used as filler, and is also widely used in daily chemical industries such as artificial floor tiles, rubber, plastics, papermaking, coatings, paints, inks, cables, building supplies, food, medicine, textiles, feed, toothpaste, etc. , used as a filler to increase the volume of the product and reduce production costs. When used in rubber, it can increase the volume of the rubber, improve the processability of the rubber, act as a semi-reinforcement or reinforcement, and can adjust the hardness of the rubber.

The application functions of heavy calcium carbonate powder 400 mesh in various industries:

1. Use in coal-fired power plant industry

Limestone flue gas desulfurization synthesizes calcium sulfite from calcium carbonate and sulfur dioxide produced during coal burning, and then oxidizes it into gypsum (calcium sulfate) when exposed to air. It can effectively reduce sulfur dioxide emissions produced by coal-fired power plants by up to 90%. The desulfurized gypsum produced can be sold directly to cement factories or gypsum board factories. The dosage of calcium carbonate desulfurization powder is related to the sulfur content in coal. Usually a 300,000-kilowatt coal-fired power plant requires 40,000 tons/year of desulfurization powder.

2. Use in putty coatings

Heavy calcium powder is used in putty coatings mainly to reduce costs, increase hardness, and is used as the main filler. Generally, heavy calcium powder is required to be about 400 to 325 mesh, and the whiteness is not less than 80%.

3. Use in feed industry

Heavy calcium powder used in the feed industry requires heavy calcium powder with a fineness of 325 mesh, whiteness requirement: 95%, calcium carbonate content: 99%, pure and without impurities. Calcium carbonate can increase the calcium content in feed and improve feed quality.

4. Use in floor tile industry

Heavy calcium carbonate (heavy calcium powder) for floor tiles: 400 mesh, whiteness requirement: 95%, calcium carbonate content: 98.5%, (pure and without impurities) calcium carbonate can be used in the floor tile industry to increase the whiteness of the product strength and tensile strength, improve the toughness of the product and reduce production costs.

5. Use in paper industry

Heavy calcium carbonate (heavy calcium powder) for papermaking requires a fineness of not less than 325 mesh, whiteness requirement: 95%, calcium carbonate content: 98%. Calcium carbonate plays an important role in the papermaking industry. It can ensure the strength and whiteness of the paper and the cost is low.

6. Use in paper industry

Heavy calcium carbonate (heavy calcium powder) for papermaking: 325 mesh, whiteness requirement: 95%. Calcium carbonate content: 98%. Calcium carbonate plays an important role in the paper industry, ensuring the strength and whiteness of paper at a low cost.

7. Use in rubber industry

Heavy calcium carbonate powder for rubber: 400 mesh, whiteness: 93%, calcium carbonate: 96%, calcium carbonate is one of the most commonly used fillers in the rubber industry. Calcium carbonate is filled in large amounts in rubber, which can increase the volume of its products and save expensive natural rubber, thus greatly reducing costs. Calcium carbonate is filled into rubber to obtain higher tensile strength, tear strength and wear resistance than pure rubber vulcanization.

8. Use in artificial marble industry

Heavy calcium carbonate (heavy calcium powder) for artificial marble: the fine base of heavy calcium powder is required to be between 325 mesh and 400 mesh, whiteness requirement: 95%, calcium carbonate content: 98.5%, (pure and impurity-free) calcium carbonate is currently widely used Used in artificial marble production.